Why Pure Water Systems Matter More Than Ever in Modern Industries

If you’ve ever stepped into a manufacturing facility, a pharmaceutical lab, or even a high-tech electronics plant, you’ll notice something curious. Amid the noise of machines and the hum of operations, there’s a quiet hero at work—water. Not just any water, but water treated to levels of purity most of us don’t think about when turning on our kitchen tap. For industries, the quality of water is not a side concern. It’s central to efficiency, safety, and sometimes even legality. And that’s where advanced purification solutions step in.

The Unsung Importance of Industrial-Grade Water

Think about a glass of water at home. If it tastes a little “off,” you might frown, maybe complain, but you’ll probably drink it anyway. Now imagine that same water being used to clean surgical tools, produce semiconductors, or mix life-saving drugs. Suddenly, a hint of chlorine or a trace of mineral residue isn’t just unpleasant—it’s unacceptable.

This is why companies invest in specialized systems that strip water of impurities to levels far beyond municipal standards. For example, a commercial deionized water system can remove dissolved salts and ions that would otherwise compromise sensitive equipment or delicate manufacturing processes. It’s the kind of behind-the-scenes infrastructure that doesn’t get flashy headlines but quietly keeps industries moving.

Deionized Water: Cleaner Than Clean

Deionized water, often shortened to DI water, goes through a process that pulls out ions—charged particles like calcium, sodium, and chloride. While those are harmless for drinking, they wreak havoc in industrial settings. In electronics, they leave conductive residues. In pharmaceuticals, they alter chemical balances. In cosmetics, they mess with formulas.

A simple example: if you’ve ever seen streaky spots on your car after washing it with regular hose water, that’s minerals drying on the surface. Now scale that problem up to a production line worth millions, and you’ll understand why DI water is such a big deal.

Of course, producing this ultra-pure water isn’t as easy as attaching a fancy filter to a faucet. It requires sophisticated resins, tanks, and often, entire treatment setups managed by professionals who specialize in DI water system installation service. Without expert oversight, even the smallest misstep can undo the whole process.

High Purity Systems and Human Ingenuity

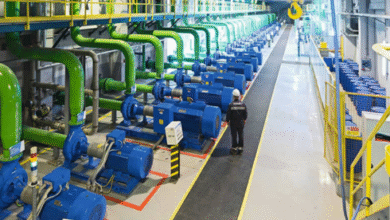

The journey to high purity isn’t just technical—it’s human. Behind every piece of polished stainless steel and every tank humming with flow meters are the people who design, build, and maintain these systems. I’ve spoken to engineers who take pride in their work like artists, explaining how a tweak in pressure or an adjustment in resin quality can transform outcomes.

That’s why companies often seek out high purity water system installers with proven track records. These aren’t just contractors; they’re problem solvers. They know how to design solutions that match unique needs—whether it’s for a biotech lab requiring sterile conditions or a brewery wanting consistent taste profiles. It’s easy to forget, but without that expertise, industries risk costly downtime or failed compliance audits.

Why Installation and Maintenance Are Non-Negotiable

Here’s the thing: a lot of people assume once a water system is installed, it’s set-it-and-forget-it. Nothing could be further from the truth. Systems need ongoing monitoring, resin regeneration, filter replacements, and sometimes reconfigurations when processes change.

Imagine a hospital lab that switches to new equipment. Suddenly, the water requirements shift. If no one recalibrates the system, the lab might run into contamination risks. The stakes are too high for “close enough.” This is why reputable providers build relationships, not just machines. They stay connected, offering service contracts and maintenance packages that ensure water purity doesn’t become tomorrow’s problem.

Real-World Scenarios Where It Matters

To really appreciate the role of high-purity water, it helps to zoom in on practical examples:

- Electronics Manufacturing: Microchips are essentially built on impossibly thin layers of material. A single mineral particle in rinse water can ruin an entire batch, costing millions.

- Healthcare and Pharma: Think vaccines, IV fluids, or even lab testing. Contaminated water could skew results or compromise patient safety.

- Food and Beverage: While flavor is the obvious factor, water quality also impacts shelf life, consistency, and regulatory approval.

- Power Plants: Boiler feedwater must be free of impurities, or else scaling and corrosion can reduce efficiency or cause dangerous failures.

These aren’t hypotheticals—they’re daily realities for industries that can’t afford mistakes. That’s why the demand for professional-grade solutions continues to grow.

The Cost Factor: Investment vs. Expense

Now, let’s talk money. Setting up a high-purity water system isn’t cheap. Some business owners balk at the upfront costs, especially when municipal water “seems fine.” But here’s the kicker: not investing can be far more expensive. Equipment failure, product recalls, compliance fines—these costs dwarf the initial investment in a well-designed system.

I once read about a brewery that learned this the hard way. They skipped proper purification, assuming their local water supply would be “good enough.” After multiple batches came out inconsistent, they had to halt production, redo recipes, and eventually call in experts to retrofit the right system. The downtime alone cost more than the system would have in the first place. It’s a lesson many industries learn: with water, quality is non-negotiable.

Looking Toward the Future of Water Purification

Technology is evolving fast. Automation, IoT monitoring, and even AI-driven diagnostics are being integrated into water purification systems. Soon, managers may get real-time alerts on their phones about resin capacity or flow rates, long before problems snowball.

But even with all the tech in the world, the basics remain unchanged: water must be pure, systems must be reliable, and skilled humans must oversee the process. If anything, the future points to closer collaboration between technology and expertise, not one replacing the other.

Final Thoughts: More Than Just Water

At the end of the day, it’s tempting to think of water treatment as just another utility. But spend a little time in the shoes of a lab technician, a brewery owner, or a microchip engineer, and you’ll realize it’s much more. It’s the silent backbone of industries that shape our lives—our health, our technology, our food, even the lights in our homes.

When you drink a bottle of medicine, boot up your laptop, or enjoy a craft beer, there’s a good chance ultra-pure water had a hand in making it possible. And that’s worth remembering. Not because we should obsess over every drop, but because the quiet work of keeping it clean allows the rest of the world to keep moving.

So, the next time you think of water, don’t just picture the tap in your kitchen. Picture the hidden systems, the teams who install and maintain them, and the industries that depend on them every single day. It’s not glamorous, but it is essential. And sometimes, that’s where the real stories are found.